Engine Control System Refit

Time to refit

A monitoring and control system of a diesel engine is subject to vibrations and high temperatures. This causes the product lifecycle of a diesel engine to differ from that of the monitoring and control system. Renewing this system will provide both technical and economic benefits and upgrade the system to the latest operational and safety standards.

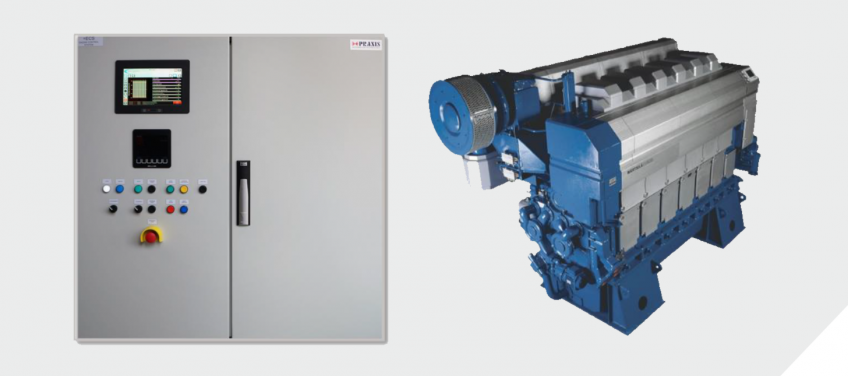

Mega-Guard ECS

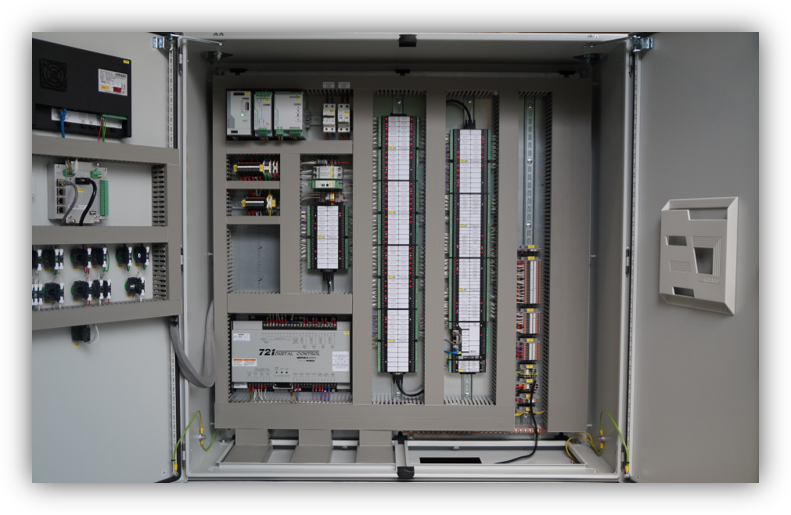

The Engine Control System is the engine room installed safety and monitoring system for the Wärtsilä W38 L and V-type diesel engines. The complete Engine Control System is built in a 1200x1200x400mm steel cabinet. All engine mounted sensors and actuators are connected to the ECS via detachable connectors in the bottom of the cabinet. Other engine room sensors/actuators and power supplies are fed directly into the cabinet. The cabinet itself is hung in 4 rubber buffers in a steel frame.

The ECS refit philosophy:

- Label and disconnect external cable wiring

- Disconnect the engine cable connectors

- Remove the original ECS cabinet from the steel frame

- Mount the new ECS cabinet in the original steel frame

- Reconnect the engine cable connectors

- Reconnect the (labelled) external cables

- Test the sensors and engine functions according to test protocol

Safety System

- The Safety System is an independent programmable system that primarily protects the operational parameters of the diesel engine.

- The Safety System main functions are:

- Automatic overspeed shutdown

- Automatic safety shutdown for engine conditions

- Automatic safety shutdown for external (e.g. gearbox) condition

- Manual emergency stop

- rpm indications

- Self-diagnostics and sensor-diagnostics

Monitoring & Control system

The Monitoring & Control system is an independent programmable system that monitors the operational parameters of the diesel engine and automates the diesel engine operations. The M&C components used, Panel PC and I/O Modules, are part of the Praxis Mega-Guard Vessel Management System product line.

The Monitoring & Control System main functions are:

- Backup safety shutdown (e.g. overspeed)

- Monitoring and alarming of potential harmful or dangerous engine parameters

- Load (rpm) reduction request in case of engine overload or deviation from normal running conditions

- Remote and local starting/stopping of the diesel engine

- Remote control via rpm setpoint

- Interface to W38 diesel engine Woodward governor system

- Standby pumps interface (for lube oil, HT/LT cooling water)

- LT cooling water thermostat control

- Self-diagnostics and sensor diagnostics

- Pre-lube oil pump control

Governor System refit options

Option 1: Preservation of original Woodward governor

Option 2: Woodward governor refit with/without Woodward actuator refit

Option 3: Praxis governor refit (replacement speed controller & actuator)

Mega-Guard Propulsion Control System (PCS)

Refitting the ECS system with the Mega-Guard ECS system is a good opportunity to also consider the refit of the vessels Remote Control System with the Mega-Guard Propulsion Control System (PCS). Because all Mega-Guard E-series systems share the same architecture and e.g. compatible network structures and common alarming indications, this offers the best integration options for both systems. All Mega-Guard E-series systems use the same hardware components which reduces the number of spare parts to a minimum.

Technical Benefits

- Improved reliability

- User friendly interface

- Latest state of the art hardware

- Safe engine operation

Economic benefits

- Lifetime extension of the diesel engine

- Reduction of spare parts

- Re-use of existing sensors

- Improvement of operational performance