GreenInverter

GreenInverter

Features

Mega-Guard GreenInverter is an advanced and compact high power inverter system covering the following drive applications:

Mega-Guard GreenInverter is an advanced and compact high power inverter system covering the following drive applications:

- Electric propulsion motor drive from DC Bus

- Generator drive and charging the GreenBatteries

- AC grid generation from DC Bus

- Shore power conversion and charging GreenBatteries

Mega-Guard GreenBatteries (electric energy storage) are connected to DC Bus. They are charged and discharged by Mega-Guard GreenInverters.

In case of grid generation and shore power conversion the GreenInverter is extended with a L-C-Transformer combination.

A GreenInverter is available in various current ranges and all of them support a DC Bus voltage up to 1000VDC and applications from 50kW up to 3000kW.

GreenInverters are available in 4 different housings from compact to medium size. DC Bus and AC cables are connected

through EMC cable glands. Multiple cable glands are installed in larger sizes GreenInverter to support parallel cables for

minimum copper use and user-friendly cable installation. Large size GreenInverters support busbar connection of DC Bus and AC side as well.

A GreenInverter with a capacity of 2000A is built up with 2x GreenInverter 1000A in parallel stack configuration and a 3000A rated GreenInverter is built-up with 3x GreenInverter 1000A in parallel providing controller redundancy as well.

High Power Inverter

Mega-Guard GreenInverter is equipped with various hardware inputs and outputs for external control and monitoring

purpose. Advanced four quadrant inverter software is applied to support sensor-less control of electric motor RPM.

A high power GreenInverter is built-up with the following main components:

- Front contains an Operator Panel and EM Stop pushbutton

- Application programming in PLC IEC61131 language

- Inverter controller with advanced four quadrant motor control software and hardware drivers for the IGBT's. Including integrated safety functions.

- IGBT's mounted on water cooling block

- DC Bus capacitors

- Powered by 24VDC

- Input and output connections: 2 x Ethernet, 8x temperature input, 1x position feedback input, 1x EM stop input and various serial ports I/O; including NMEA, MODBUS (RS485),

J1939 or CAN Open

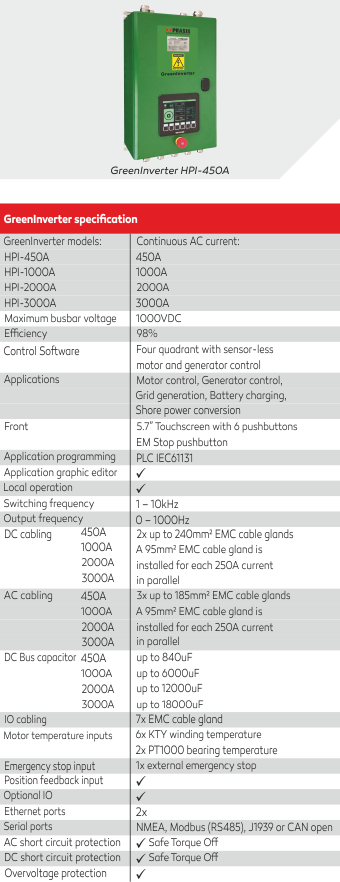

Specification

View a list of our worldwide sales and service network.

Praxis Automation Technology

Zijldijk 24A,

2352 AB Leiderdorp

The Netherlands

+31 (0)71 5255 353

Spare parts:

parts@praxis-automation.com

Information/questions:

info@praxis-automation.com

More contact details